What is an PQCDSM Board?

PQCDSM is an acronym used in Total Productive Maintenance (TPM) and manufacturing to represent six key performance indicators: Productivity, Quality, Cost, Delivery, Safety, and Morale. These six areas are monitored to ensure efficient and effective operations.

- Performance: Driving operational excellence by continuously monitoring and enhancing key performance metrics to ensure efficiency and overall effectiveness in all areas.

- Quality: Upholding the highest standards of quality through rigorous testing, continuous process improvements, and a focus on defect reduction to deliver superior products and services.

- Cost: Maximising financial efficiency by optimising resource allocation, reducing waste, and ensuring cost-effective operations without compromising on quality or safety.

- Delivery: Ensuring reliable and on-time order fulfillment by streamlining processes, improving lead times, and addressing bottlenecks to meet customer expectations consistently.

- Safety: Maintaining a safe work environment by identifying potential hazards, implementing proactive risk mitigation strategies, and ensuring compliance with safety standards to prevent incidents and promote employee well-being.

- Morale: Cultivating a positive, engaged, and motivated workforce through strong communication, team collaboration, and a focus on employee well-being and growth opportunities.

Productivity

Productivity focuses on maximising output and efficiency by refining operations, promoting a culture of ongoing improvement, and ensuring optimal resource utilisation. It enhances performance through process optimisation, active employee involvement, and the standardisation of practices to deliver consistent and high-quality results.

- Maximising Output

- Enhancing Process Efficiency

- Optimising Resource Utilisation

- Fostering Employee Engagement

- Standardising Operational Procedures

Quality

The Balanced Scorecard’s quality metrics provide a comprehensive assessment of both product and process performance. By tracking defects, inspection failures, rework rates, non-conformance reports, and incorporating feedback from both suppliers and customers, organisations can strengthen their quality assurance practices and cultivate an ongoing culture of improvement.

- Detected Product Defects

- Failed Quality Inspections and Functional Testing

- Documented Rework Activities and Corrective Actions

- Issued Non-Conformance Reports (NCRs) for Compliance

- Identified Quality Issues in Supplier-Sourced Materials

Cost

Effective strategic cost management is critical for sustaining financial stability and fostering long-term profitability. The Balanced Scorecard provides a systematic approach to tracking and analysing key financial metrics, enabling organisations to identify cost-saving opportunities, maintain strict budget adherence, and make data-driven decisions that optimise both operational and financial performance.

- Execution of Cost Reduction Initiatives

- Comprehensive Monitoring of Expenses

- Enhancement of Operational Cost Efficiency

- Strict Oversight of Budget Compliance

- Optimised Allocation and Utilisation of Resources

Delivery

The Balanced Scorecard offers a holistic view of the entire delivery process, ensuring reliable On Time In Full (OTIF) performance from the initial supplier shipment to final customer receipt. It assesses the efficiency of logistics, the accuracy of order fulfillment, and inventory flow, providing valuable insights that help optimise supply chain operations and enhance strategic decision-making.

- Identification and Analysis of Late Deliveries

- Tracking On Time In Full (OTIF) Performance

- Evaluation of Order Fulfillment and Dispatch Accuracy

- Assessment of Warehouse Efficiency and Inventory Turnover

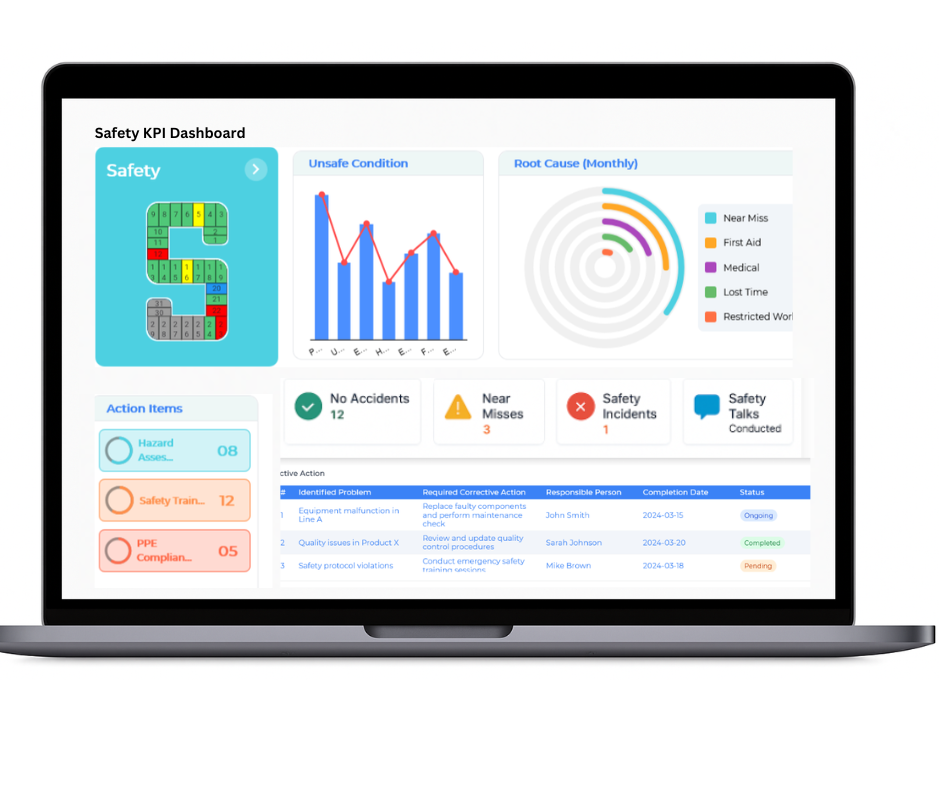

Safety

The Balanced Scorecard is instrumental in enhancing workplace safety by continuously tracking safety incidents. By monitoring accidents and near-miss events, it provides actionable insights into the effectiveness of current safety measures and identifies opportunities for improvement.

- Total Number of Workplace Accidents Reported

- High-Risk Near-Miss Incidents Documented

- Completed Root Cause Analysis for Safety Incidents

- Number of Safety Briefings and Training Sessions Conducted

Morale

The Balanced Scorecard plays a crucial role in enhancing employee morale by tracking key factors such as job satisfaction, teamwork, and overall engagement. By regularly assessing these metrics, organisations can foster a positive work environment, increase productivity, and ensure long-term team success.

- Employee Engagement and Satisfaction Levels

- Effectiveness of Team Collaboration and Communication

- Retention and Turnover Rates with Analysis

- Programs Promoting Employee Health and Well-Being

- Opportunities for Training, Learning, and Career Development

PQCDSM Board for Shift Management

- Real-Time Performance Monitoring: Tracks key operational metrics across Productivity, Quality, Cost, Delivery, Safety, and Morale to ensure continuous alignment with strategic objectives.

- Proactive Safety Management: Monitors incidents, near-misses, and safety audits to strengthen workplace safety practices and mitigate risks across all operations.

- Quality Excellence at Every Stage: Measures defect rates, rework patterns, and adherence to quality standards to drive continuous product and process improvement.

- Delivery Optimisation: Monitors On Time In Full (OTIF) performance, identifies delays, and enhances scheduling accuracy to ensure timely order fulfillment.

- Cost Management and Resource Optimisation: Assesses cost efficiency, resource utilisation, and waste reduction to improve profitability and ensure budget control.

- Employee Morale and Engagement: Evaluates employee satisfaction, teamwork, training progress, and engagement to cultivate a positive work culture and improve performance.

- Sustainability and Environmental Impact: Monitors energy consumption, waste management, and emissions to promote sustainability and meet environmental regulations.

What Does PQCDSM Stand For? Understanding Key Performance Indicators

PQCDSM is a performance management framework used by organisations to track and improve key metrics across various operational areas. It focuses on essential factors that drive business success, helping teams optimise performance and achieve their goals efficiently. Let’s break down what each letter stands for and how it contributes to overall performance.

Performance Quality (P)

The 'P' in PQCDSM stands for Performance Quality, which refers to the ability to meet customer expectations and deliver products or services that meet predefined standards. It ensures that the final output is reliable, defect-free, and in line with the company’s quality objectives.

Quality (Q)

Quality is a key pillar in any operational framework. It measures the consistency of processes and products, helping teams identify any defects or inefficiencies. Focusing on quality helps companies maintain high standards and ensure customer satisfaction.

Cost (C)

Cost management is crucial for sustainable business growth. The 'C' in PQCDSM focuses on controlling operational costs while ensuring that quality and performance standards are maintained. Monitoring costs helps identify areas where savings can be made without compromising on output.

Delivery (D)

Delivery focuses on how efficiently goods or services are provided to customers. Tracking delivery performance helps ensure that products are delivered on time, within budget, and to the expected quality standards.

Safety (S)

Safety metrics are crucial for maintaining a secure work environment. By tracking safety incidents, organisations can reduce risks, prevent accidents, and foster a safer workplace for all employees.

Morale (M)

Morale measures employee engagement and satisfaction. High morale leads to higher productivity, reduced turnover, and better overall performance. It’s essential for ensuring that teams remain motivated and focused on achieving business goals.

PQCDSM provides a comprehensive approach to performance tracking, allowing organisations to make informed decisions and drive continuous improvement across all aspects of their operations.

How a PQCDSM Board Helps Enhance Operational Efficiency Across Industries

A PQCDSM board is an effective tool for improving operational efficiency across industries by focusing on key performance indicators (KPIs) that drive continuous improvement. This visual management tool helps teams track and optimise performance in critical areas, ensuring that businesses stay competitive and achieve their objectives more efficiently.

Performance Quality (P)

By monitoring Performance Quality, organisations can quickly identify areas where their output may fall short of customer expectations. Whether in manufacturing or service delivery, this ensures that any issues are addressed promptly, enhancing overall product or service quality.

Quality (Q)

The focus on Quality helps organisations maintain consistency and high standards across their processes. By regularly reviewing quality metrics, teams can spot defects, reduce waste, and refine their workflows, leading to improved product reliability and customer satisfaction.

Cost (C)

Cost management is a critical element of any successful business. A PQCDSM board helps track operational costs and highlights areas where savings can be made without affecting performance. This promotes cost-effective strategies, reducing unnecessary expenses and increasing profitability.

Delivery (D)

Ensuring timely delivery of products or services is essential for maintaining customer trust and satisfaction. The delivery aspect of the PQCDSM board helps organisations measure and optimise lead times, ensuring that they meet customer expectations and improve service reliability.

Safety (S)

Safety is a fundamental aspect of any operation. The PQCDSM board helps track safety incidents, allowing businesses to implement proactive measures to reduce risks, ensure compliance, and create a safer working environment for employees.

Morale (M)

Employee morale is directly linked to productivity and efficiency. By tracking morale, companies can identify areas that may need improvement in workplace culture, leading to higher engagement, lower turnover, and better performance.

Incorporating a PQCDSM board into daily operations helps organisations optimise their processes, reduce inefficiencies, and drive continuous improvement, ultimately enhancing operational efficiency across various industries.

The Importance of Safety (P) in PQCDSM: Prioritising a Safe Work Environment

In any organisation, prioritising safety is crucial for the well-being of employees and the smooth running of operations. The Safety (P) aspect of the PQCDSM framework helps businesses identify and mitigate risks, fostering a safe work environment that reduces accidents and ensures compliance with regulations.

Proactive Risk Management

The Safety (P) metric within PQCDSM focuses on actively managing potential hazards before they escalate into serious incidents. Regular monitoring and assessment of safety practices help identify weak points in the system, allowing organisations to take preventive measures and reduce workplace injuries. A proactive approach not only protects employees but also minimises costly disruptions to operations.

Boosting Employee Confidence

When employees feel safe in their work environment, they are more likely to be engaged, productive, and motivated. By emphasising safety through the PQCDSM board, businesses demonstrate their commitment to the well-being of their workforce, which can lead to increased employee satisfaction and retention.

Compliance and Reputation

Ensuring workplace safety is not just a moral responsibility; it is also a legal obligation. Tracking safety metrics helps organisations remain compliant with industry standards and government regulations, protecting them from potential legal issues and fines. Furthermore, maintaining a strong safety record enhances the company’s reputation as a responsible and ethical employer.

In conclusion, integrating Safety (P) into the PQCDSM board is a vital step in prioritising employee well-being, improving workplace morale, and maintaining operational efficiency. A safe working environment leads to fewer disruptions, lower costs, and a more productive workforce.

Quality (Q): Ensuring Consistent and High-Quality Output with PQCDSM

Quality (Q) is a key pillar in the PQCDSM framework, focusing on delivering products and services that consistently meet or exceed customer expectations. Ensuring high quality in every aspect of production or service delivery helps businesses build trust, improve customer satisfaction, and boost long-term success.

Maintaining High Standards

The Quality (Q) metric within the PQCDSM board allows organisations to establish clear quality standards and monitor performance against these benchmarks. By setting specific quality goals and regularly assessing outputs, businesses can identify any deviations early and take corrective actions. This commitment to quality leads to a consistent and reliable product that customers can trust.

Continuous Improvement

Incorporating Quality (Q) into the PQCDSM board fosters a culture of continuous improvement. Regularly tracking quality metrics encourages teams to refine processes, eliminate inefficiencies, and enhance product quality over time. This process not only reduces defects but also ensures that products meet changing customer needs and market demands.

Reducing Costs and Waste

When quality control is integrated into operations, businesses can reduce waste and prevent costly rework or returns. High-quality products are less likely to have defects or require re-manufacturing, leading to cost savings and improved operational efficiency. This reduction in waste also contributes to a more sustainable production process.

Cost (C): Tracking and Reducing Costs Effectively Using PQCDSM

Cost (C) plays a crucial role in the PQCDSM framework, allowing businesses to monitor and manage their expenses while optimising operational efficiency. By keeping track of costs, organisations can identify areas for improvement, reduce waste, and enhance profitability. The Cost (C) metric ensures that businesses can stay competitive while maintaining high-quality standards.

Efficient Resource Management

Through the Cost (C) component of the PQCDSM board, businesses can analyse how resources are utilised and whether any areas are leading to unnecessary expenditure. This information allows organisations to make informed decisions about resource allocation, helping to avoid overuse of materials, excessive labour costs, or inefficiencies in the production process. Tracking these costs ensures that businesses can maximise output without overspending.

Identifying and Reducing Waste

Effective cost management isn't just about reducing expenses—it’s also about eliminating waste. By regularly assessing costs, businesses can pinpoint where waste occurs, whether it's in production, transportation, or handling. By targeting these areas for improvement, businesses can reduce operational inefficiencies, cut down on excess inventory, and avoid unnecessary spending.

Improving Profit Margins

Reducing costs directly impacts a company’s bottom line. By improving cost efficiency, organisations can increase profit margins without compromising on quality. This approach helps maintain competitive pricing while still delivering excellent products and services to customers, boosting both profitability and customer satisfaction.

Delivery (D): Meeting Deadlines and Customer Expectations with PQCDSM

Delivery (D) is a vital component of the PQCDSM framework, focusing on the timely and efficient fulfilment of customer orders and expectations. Timeliness is crucial for maintaining customer satisfaction, building trust, and staying competitive. By monitoring delivery performance, businesses can ensure that products or services are delivered on schedule, fostering long-term relationships with clients and customers.

Ensuring Timely Delivery

The Delivery (D) metric in the PQCDSM board enables businesses to track key performance indicators related to deadlines and delivery times. This ensures that orders are fulfilled promptly, reducing delays that could lead to customer dissatisfaction. Timely delivery also helps businesses stay ahead of competitors, providing an edge in industries where speed is critical.

Meeting Customer Expectations

Effective delivery management not only focuses on speed but also on meeting the quality expectations of customers. Delivery (D) allows businesses to assess whether the delivered product or service aligns with the customer’s requirements. By keeping track of performance and feedback, businesses can adjust processes to enhance customer satisfaction and ensure consistent service levels.

Optimising Logistics and Processes

With the Delivery (D) component, businesses can identify bottlenecks and inefficiencies in their supply chain or operations. This insight allows organisations to streamline logistics, improve order processing, and optimise inventory management. Such improvements lead to smoother operations and better overall delivery performance, helping to meet deadlines consistently.

Safety Management (S): How PQCDSM Boards Improve Safety Standards

Safety Management (S) is a key element of the PQCDSM framework, designed to prioritise the safety and well-being of employees and stakeholders within an organisation. By closely monitoring safety performance, businesses can identify potential hazards, track incidents, and implement proactive measures to create a safer work environment. Ensuring safety is not only a legal requirement but also essential for maintaining employee morale and reducing workplace accidents.

Tracking Safety Performance

The Safety Management (S) metric on PQCDSM boards allows organisations to track safety-related data, including the frequency of accidents, near misses, and safety violations. This data provides a clear picture of the safety culture within the company, allowing managers to identify trends and areas for improvement. Regularly reviewing safety metrics helps businesses stay ahead of potential risks and ensure a safer environment for everyone.

Promoting a Safety-First Culture

By integrating Safety Management (S) into the PQCDSM board, organisations can foster a culture that prioritises safety. Employees are more likely to take safety seriously when they see it being tracked and measured at the team and organisational levels. The visibility of safety data encourages greater awareness and accountability, leading to better safety practices across the workplace.

Preventing Accidents and Reducing Risks

With a focus on safety, businesses can take proactive steps to prevent accidents before they occur. The PQCDSM board helps identify common safety issues, allowing organisations to address these concerns through targeted interventions, training, and improved safety protocols. As a result, organisations can significantly reduce the number of workplace injuries, contributing to a healthier and more productive work environment.

Maintenance (M): Minimising Downtime and Maximising Uptime with PQCDSM

Maintenance (M) is a crucial aspect of the PQCDSM framework, focusing on optimising equipment performance and reliability. The goal is to minimise downtime, reduce maintenance costs, and ensure that machines and systems are operating at their best. By actively monitoring and managing maintenance activities, businesses can improve productivity, reduce unexpected breakdowns, and maximise the longevity of their assets.

Tracking Maintenance Metrics

The Maintenance (M) metric on PQCDSM boards provides businesses with real-time insights into the health of their equipment and machinery. This includes tracking downtime, identifying frequent failures, and monitoring the success of maintenance interventions. By visualising these metrics, businesses can quickly pinpoint areas that require attention and take action before minor issues turn into major problems.

Proactive Maintenance to Prevent Downtime

By integrating proactive maintenance into the PQCDSM framework, businesses can shift from reactive repairs to planned, preventative actions. Regular inspections, timely repairs, and scheduled maintenance tasks help prevent unplanned downtime, which can disrupt operations and lead to costly delays. Proactive maintenance also reduces the need for expensive emergency repairs, helping businesses save money in the long run.

Maximising Equipment Uptime

Maximising uptime is essential for maintaining efficient operations. With PQCDSM, organisations can track and optimise their maintenance schedules to ensure that equipment is available when needed. By ensuring that machinery is always in good working condition, businesses can maintain smooth production processes, meet deadlines, and improve customer satisfaction.

Why PQCDSM is Essential for Streamlined Production Processes and Monitoring

PQCDSM is an invaluable framework for organisations aiming to optimise production processes and ensure efficient monitoring of key performance metrics. By focusing on five critical areas—Safety, Quality, Cost, Delivery, Safety Management, and Maintenance—PQCDSM provides a structured approach that helps businesses drive continuous improvement while maintaining high operational standards.

Streamlining Production Processes

The PQCDSM board allows companies to visualise and monitor essential production data in real-time, helping them identify inefficiencies and bottlenecks. By tracking safety incidents, quality standards, and maintenance schedules, organisations can take proactive steps to improve workflow and prevent delays. This clarity enables better decision-making, ensuring that production runs smoothly and that teams can respond swiftly to challenges.

Improved Monitoring and Performance Tracking

With the PQCDSM framework, businesses can track performance metrics such as product quality, cost control, and delivery timelines. Monitoring these key performance indicators (KPIs) in real-time ensures that issues are detected early and addressed promptly. As a result, businesses can minimise waste, reduce downtime, and ensure that products are delivered on time and meet customer expectations.

Boosting Efficiency Across Departments

The integration of PQCDSM into production processes fosters a collaborative environment. Cross-departmental teams work together to maintain safety standards, monitor quality, control costs, and manage delivery schedules. This alignment ensures that everyone is focused on the same organisational goals, which ultimately leads to streamlined operations and increased overall efficiency.

Tracking Performance Metrics in Real-Time: The Role of PQCDSM Boards

PQCDSM boards are essential tools for organisations looking to track key performance metrics in real-time, ensuring that production processes remain efficient and responsive. By providing a clear visual representation of key areas such as Safety, Quality, Cost, Delivery, Safety Management, and Maintenance, PQCDSM boards enable teams to monitor performance continuously and make data-driven decisions quickly.

Real-Time Monitoring for Smarter Decisions

Real-time tracking allows businesses to identify potential issues as they arise. Whether it's a safety concern, a quality issue, or a delay in delivery, PQCDSM boards provide immediate insights into the status of each key metric. This allows teams to take swift action, minimising downtime and ensuring that the production process stays on track.

Ensuring Consistent Quality and Cost Control

Quality and cost are two of the most critical factors in any production environment. By using a PQCDSM board, organisations can continuously track product quality and operational costs, ensuring that they meet set standards and budgets. Regular updates help highlight areas where costs are exceeding expectations or quality may be slipping, enabling timely corrective actions to maintain high standards.

Improved Collaboration Across Teams

With PQCDSM boards, all departments involved in production can stay informed about performance metrics in real-time. This transparency fosters better collaboration between teams, allowing for quicker resolutions to any issues that arise. By aligning everyone towards common goals, PQCDSM boards help create a unified approach to operational success.

The Role of PQCDSM in Supporting Lean Manufacturing Principles

PQCDSM is a powerful tool that aligns seamlessly with lean manufacturing principles by providing a clear, real-time view of key performance metrics. The PQCDSM framework focuses on five critical areas—Safety, Quality, Cost, Delivery, Safety Management, and Maintenance—that directly support lean objectives such as waste reduction, process optimisation, and continuous improvement.

Eliminating Waste and Improving Efficiency

One of the core goals of lean manufacturing is to eliminate waste across the production process. PQCDSM boards help organisations monitor key metrics in real-time, allowing them to identify inefficiencies and take immediate corrective action. For example, tracking maintenance schedules on the board ensures equipment is properly maintained, reducing unplanned downtime and improving overall efficiency.

Ensuring High Quality and Cost Control

Quality control is integral to lean manufacturing, and PQCDSM boards make it easy to track quality metrics consistently. By monitoring quality standards and identifying potential issues early, businesses can reduce defects and rework, which directly impacts cost savings. Additionally, by tracking cost-related metrics, companies can identify areas where expenses can be minimised, further aligning with lean manufacturing goals.

Improved Delivery and Customer Satisfaction

Meeting customer delivery expectations is another key lean principle, and PQCDSM boards ensure that businesses stay on track. By tracking delivery metrics in real-time, organisations can identify delays and take immediate action, helping to meet customer deadlines and improve overall satisfaction.

How PQCDSM Boards Drive Continuous Improvement and Long-Term Success

PQCDSM boards are essential for fostering a culture of continuous improvement within any organisation. By tracking key metrics in real time, they provide valuable insights that help businesses identify areas for growth and implement actionable improvements across all departments. The six metrics—Safety, Quality, Cost, Delivery, Safety Management, and Maintenance—work together to create a comprehensive view of organisational performance, allowing businesses to continuously enhance their operations.

Empowering Teams to Take Action

The visual nature of PQCDSM boards makes performance data easily accessible, encouraging teams to take ownership of their performance metrics. When teams see real-time data on safety incidents, quality control, or maintenance schedules, they can immediately address issues, reducing downtime and improving productivity. This sense of ownership motivates employees and drives continuous improvement across the organisation.

Identifying and Addressing Inefficiencies

By monitoring the key areas of Safety, Quality, Cost, Delivery, Safety Management, and Maintenance, organisations can quickly identify inefficiencies or areas that need attention. Whether it’s identifying frequent equipment breakdowns, cost overruns, or delays in delivery, PQCDSM boards offer a clear and immediate overview that helps leaders make informed decisions, take corrective actions, and implement solutions that prevent future issues.

Long-Term Success Through Consistent Monitoring

Continuous improvement isn’t a one-off effort; it’s a long-term strategy. PQCDSM boards allow businesses to consistently track their performance, ensuring they remain on course to achieve their long-term goals. By using these boards to monitor and analyse key metrics, organisations can continuously fine-tune their processes, improve efficiency, and ensure sustained success.

Visualising Key Metrics: Why PQCDSM Boards Are Essential for Team Engagement

In today's fast-paced work environment, effective team engagement is key to driving performance and achieving operational goals. PQCDSM boards play a pivotal role in this by providing a clear, visual representation of key metrics that impact day-to-day operations. By displaying data on Safety, Quality, Cost, Delivery, Safety Management, and Maintenance, these boards empower teams to stay focused on what matters most and collaborate effectively towards continuous improvement.

Clear, Real-Time Insights

One of the most valuable features of PQCDSM boards is their ability to present real-time data in a simple, accessible format. Whether it's tracking safety incidents, monitoring quality control, or managing maintenance schedules, the visibility of key metrics ensures that everyone is on the same page. When teams can instantly see the status of critical performance indicators, they are more likely to take proactive steps to improve processes, address challenges, and meet targets.

Encouraging Accountability and Ownership

Having key metrics visible on PQCDSM boards promotes a sense of ownership and accountability among team members. When everyone can see how their work impacts overall performance, they are more motivated to contribute to achieving organisational goals. This transparency fosters a collaborative culture, where teams actively work together to solve problems and achieve continuous improvement.

Boosting Engagement and Morale

Regularly updated PQCDSM boards create a dynamic environment that keeps employees engaged. Seeing progress and understanding how their actions directly contribute to business success boosts morale and fosters a positive, results-driven culture.

How to Implement PQCDSM Boards for Effective Production Management

Implementing PQCDSM boards in your production management process can significantly improve team collaboration, efficiency, and performance tracking. These boards offer a structured approach to monitor and improve key performance metrics, including Safety, Quality, Cost, Delivery, Safety Management, and Maintenance. Here’s how you can get started:

Step 1: Define Key Metrics

The first step is to identify the most important metrics for your production process. These include Safety (P), Quality (Q), Cost (C), Delivery (D), Safety Management (S), and Maintenance (M). Understanding the specific needs of your operations will guide which data to focus on and how to set measurable goals for each area.

Step 2: Set Up the Board

Design your PQCDSM board to display each metric clearly. This can be done using a physical whiteboard or a digital platform, depending on your team’s preferences. Ensure each section is easily visible and includes real-time data or performance updates to keep everyone informed. This promotes transparency and accountability.

Step 3: Train Your Team

Once your board is set up, train your team on how to use it effectively. Encourage regular updates and discussions about the metrics. This helps everyone understand their roles and how they contribute to meeting production goals. The more engaged your team is with the board, the more likely they are to take ownership of improving performance.

Step 4: Regular Review and Improvement

Schedule regular reviews to assess performance and identify areas for improvement. Use the insights from the PQCDSM board to make data-driven decisions, optimise processes, and drive continuous improvement in your production operations.

Industry-Specific Applications: How PQCDSM Boards Benefit Various Sectors

PQCDSM boards are powerful tools that support performance monitoring and improvement across a wide range of industries. By focusing on six essential pillars—Productivity, Quality, Cost, Delivery, Safety, and Maintenance—these boards help teams stay aligned, make informed decisions, and drive continuous improvement. Here’s how different sectors benefit from PQCDSM boards.

Manufacturing

In the manufacturing sector, PQCDSM boards provide daily visibility into shop floor performance. Teams can track production rates, machine maintenance, safety incidents, and delivery timelines. This helps reduce downtime, improve product quality, and ensure on-time order fulfilment, all while keeping costs under control.

Healthcare

Healthcare organisations use PQCDSM boards to monitor patient safety, care quality, resource usage, and service delivery times. By making data visible and accessible to all staff, these boards support better decision-making, timely interventions, and improved patient outcomes.

Logistics and Warehousing

In logistics, delivery and safety are key performance areas. PQCDSM boards help teams monitor daily dispatch targets, delivery efficiency, operational costs, and equipment upkeep. This leads to smoother workflows, fewer delays, and safer work environments.

Food Processing

Food processing facilities benefit from PQCDSM boards by tracking hygiene standards, product consistency, and timely order processing. This ensures both food safety and operational excellence.

Regardless of the industry, PQCDSM boards create a culture of visibility, accountability, and proactive problem-solving—helping teams work smarter every day.